Elevating Manufacturing Efficiency

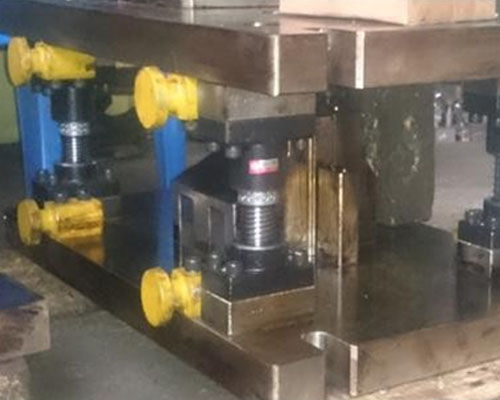

A Deep Dive into CNC Double Column Machining Product Highlights from Sri Stars CNC Double Column Machining Center.

- Travels of up to 236″ x 166″ x 60″ (6000 x 4200 x 1500 mm)

- Table sizes of up to 236″ x 134″ (6000 x 3400 mm)

- Box-in-box unity cast-iron frame

- Extended Y travel for auto 5F machining.

- All linear guide ways for enhanced rigidity and accuracy

- Double layer loop frame table

- Optimal spindle box (ram) design: 450 x 400mm²

- Heavy duty ram size of up to 650 x 650 mm²

CNC Double Column Vertical Machining Centers combine proven machine design with advance technology in control and manufacturing in Chennai. Reliability and performance make this series a favorite among demanding CNC milling job shops and in-house productions alike. The heavy cutting spindle and rigid machine structure enable higher vertical machining efficiency with better finish and longer tool life – resulting in greater productivity and profitability all around.

Advantages of CNC Double Column Machining Center

CNC (Computer Numerical Control) Double Column Machining Centers offer several advantages in precision machining and manufacturing processes.

CNC technology ensures extremely high precision in machining operations, leading to accurate and consistent finished products. Double column design provides enhanced stability and reduces the chances of vibrations, contributing to better machining accuracy.

- Double column machining centers are versatile and can handle a wide range of materials, from metals to composites, making them suitable for various industries such as aerospace, automotive, and mold making. They can accommodate large workpiece due to their spacious work envelopes and high load capacities.

- CNC automation allows for continuous and efficient production runs with minimal downtime between different machining operations.

- Simultaneous multi-axis machining capabilities enable the completion of complex parts in a single setup, reducing overall machining time.

- CNC controls facilitate quick and precise tool changes, reducing setup times between different machining processes.

- Automatic tool changers and part probing systems contribute to faster and more efficient setup procedures.

- High spindle speeds and rapid traverse rates enable faster cutting speeds, leading to shorter cycle times and increased productivity.

- Improved acceleration and deceleration rates contribute to quicker positioning of the tool, reducing non-cutting time.

- CNC machining centers can optimize cutting parameters, leading to longer tool life and reduced tooling costs.

- Advanced tool monitoring and wear detection systems help prevent tool breakage and enhance overall machining efficiency.

- The multi-axis capability of double column machining centers allows for the production of complex geometries and intricate parts.

- 5-axis machining capability enables the tool to reach multiple faces of a workpiece without repositioning, reducing the need for additional setups.

- CNC programming ensures that each part produced is identical to the digital model, providing consistency in quality and adherence to design specifications.

- CAD/CAM integration simplifies the programming process, allowing for the efficient translation of design specifications into machine instructions.

- CNC programming can be standardized and reused for similar parts, reducing programming time for subsequent projects.

- CNC machining centers often come equipped with safety features, such as interlocks and emergency stop buttons, to ensure the well-being of machine operators.

In summary, CNC Double Column Machining Centers offer a combination of precision, versatility, productivity, and automation, making them suitable for a wide range of applications in modern manufacturing.